100 %

natural raw material

sustainable production

uncompromising quality

international availability

fair conditions

trusted safety

leading distributors

individual processing

timeless material

The split leather of the next generation

Our unique refining method allows us to create a split leather product like no other in the global marketplace. By combining nature and technology, we achieve unprecedented diversity and high quality in the production of first-rate interior components. All positive characteristics of high quality split leather are merged with high-end technology, resulting in an innovative product that sets new standards.

100 %

Our leather is certified as 100 % leather to DIN EN 15987 It also meets all requirements of DIN EN 16233 regarding the designation and description of leather for upholstery as well as automobile interiors.

The grain leather with the best characteristics

Our grain leather offers all the characteristics expected of first-rate leather. Furthermore, it boasts additional features that make it ideal for the production of interior components meeting the highest demands. By selecting only the best base materials and using only state-of-the-art methods, we make exceptional grain leather products for the transport sector.

100 %

Our leather is certified as 100 % leather to DIN EN 15987 It also meets all requirements of DIN EN 16233 regarding the designation and description of leather for upholstery as well as automobile interiors.

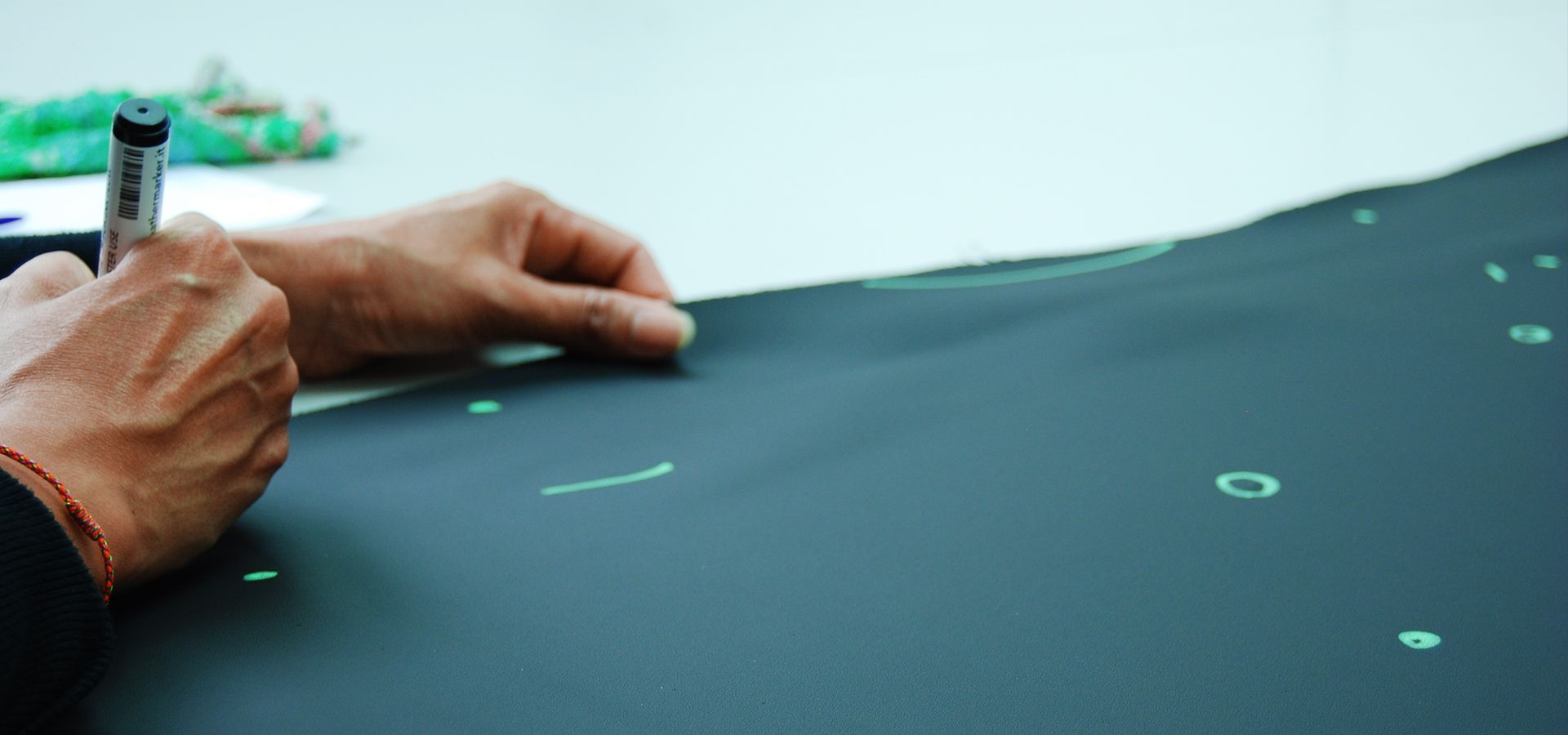

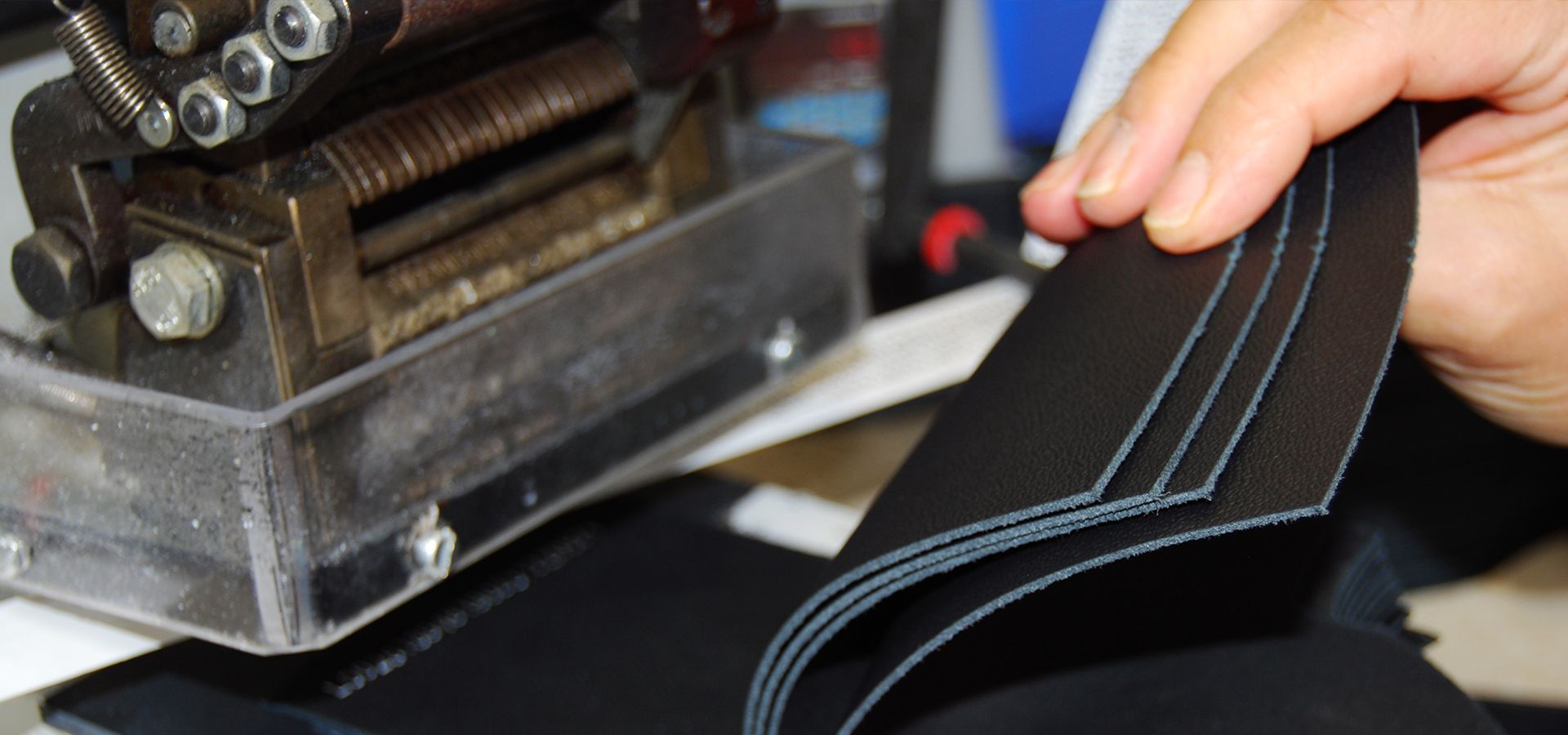

We give your leather the right shape

In our stamping plant, we process your leather into accurately dimensioned stamped parts. It is a great advantage for us to be able to offer our customers this next step of the production chain. This ensures fast and easy further processing of both small and large runs.